The 8-Day Transformation of our Victory 21’ Sailboat

My heart pounded as adrenaline rushed through my veins, the wind kissing my cheeks as we thread through the oncoming vessels fighting for our position. It was the 68th annual High Sierra Regatta, marking half a decade of crewing together aboard Chris’s (now our) Victory 21’ sailboat. Out of all the summers racing on Huntington Lake, this was bound to be the most memorable. Why? Because the real race was not the one on the water, but the one we had just finished one day prior to getting there.

Will Parker: What’s wrong with perfection?

Joe Heiser: Nothing, if you’re God, and you’re prepared to wait 500 million years for it to evolve. But we have to start building this boat next week.”

High Sierra Regatta 2019

“Just bottom paint.” Chris said definitively as I looked at him with my best pouty face that said “please” without actually vocalizing it. After years of discussion surrounding the much-needed refit of our Victory 21 we had decided to give her a proper bottom job, but of course, I was hoping (and begging) that it would turn into a topside job as well. Having just removed her 300-pound lead “bubble” off her keel two summers prior (an hour before the race) we hadn’t had time to actually finish the job. Her jagged keel was sprayed with snowmobile paint in hopes to protect her temporarily from further decay, and it did well as a temporary fix. We actually held 4th place throughout the entire regatta, only forfeiting when our rig failed on an upwind leg due to a chainplate malfunction… We will address that later. Christopher (the name of the boat) was showing her age and wore her exposed fiberglass-like battle scars, a reminder of collisions and close calls at the mark. Her beautiful dark hull that Chris and his father had painted many moons ago was not as glorious as it once was, displaying spider cracks and chips throughout the hull carrying down to her underside where no paint was to be found beside the patches of snowmobile paint from our attempted fix. Her rigging was old, the jam cleats were missing “claws” and her sheets were crusty from being baked in the Fresno sun where she sat “dry docked” on her custom trailer at “Uncle” Scooters amongst the other boats, cars, and collectible things.

It was 4 am and we had been up for an hour already, our weary eyes growing heavy as we connected the tow hitch to the trailer. Our little Victory was secure and ready for her four-hour road trip to Southern California where we would spend two weeks preparing her for the High Sierra Regatta. The Ventura Harbor Boat Yard had set up a spot for us to work on the boat and seemed excited to welcome us back so soon after our haul out on Avocet in 2020. We spent the first day dissecting Christopher’s rigging and fittings, preparing for the weeks to come. Chris measured for the materials we would need and we relocated the mast to sand it down to bare aluminum. I sat in the cockpit analyzing her broken jam cleats and trying to remember how I whip the sheets to release them when tacking in an attempt to find a better configuration that would give us some mechanical advantage. Truth be told (and to our fleets amazement) I have been known to not use winches and pull the sheets by hand which gives us a quicker response, but in retrospect after all I have learned aboard Avocet that is probably exactly why our cleats broke; the sheets were overloading them whereas using the winch before the cleat would alleviate the pressure. Note to self: winches are your friend.

I walked through the boatyard with my work sweater in my arm as I struggled to pull on my project flannel in preparation of getting my hands dirty. The sounds of heavy machinery and the smell of resin were a shot of nostalgia reminding me of our boatyard days on Avocet. Tucked away in the corner of the yard was our Victory, hidden behind Chris’s truck. I knocked on the hull “Chris? Are you here?” and almost instantaneously his head popped up from the shallow depths of the boat’s “cabin.” Chris shook off as fiberglass dust puffed in a cloud surrounding him, similar to what you see in cartoons. With every step, he took coming down the ladder more dust blew off of him. He was covered in fiberglass from head to toe, no longer feeling the notorious itch from having worked with it for so long. At a distance, I asked what I could do to which he responded with “just keep me company while I glass” so I pulled out my notes and read him an article I discovered regarding the history of the very boat we were working on:

“Frank Butler founded Catalina Yachts in North Hollywood, CA, in 1969. Now headquartered in Largo, FL, but with offices still in Woodland Hills, CA, Catalina Yachts has grown to become the largest manufacturer of production fiberglass sailboats in the United States, floating more than 85,000 yachts to date. In his lifetime, Frank Butler has introduced hundreds of thousands of people to the sport of sailing. Frank began his career in the U.S. Navy and then went to college in 1948, but it wasn’t for him. Instead, he opened his own machine shop called Wesco Tool where he enjoyed great success making airplane parts. In 1949, Frank met and married his wife of 71 years, Jean, and started a family that would eventually lead to seven children. As his family grew, he needed a bigger boat! In 1959, Frank contracted with Henry McCune Shipbuilders to build a Victory 21 sloop, designed by naval architect Ted Carpenter. McCune ran out of funds so he gave Frank the tooling to continue building his boat by himself. By 1962, Frank had built 126 Victory 21s that led to founding his next company, Wesco Marine, in 1964. In 1966, Frank changed Wesco Marine into Coronado Yachts and built the Coronado 25. This was Frank Butler’s first notable boat design, incorporating his knowledge from his work in the airplane industry at Wesco Tool. In 1967, Frank purchased Columbia Yachts and then sold Coronado Yachts in 1968. Finally, after its founding in 1969, Catalina Yachts shifted all manufacturing rights out of Wesco Marine, which still exists today as a supplier of rigging hardware for Catalina Yachts. Once at Catalina, the Victory 21 was rebranded as the Catalina Capri 21 Victory”

As I finished the last sentence our friends Quincey and Mitch from Esprit walked up to check out “our” progress. We had convinced them to join us in the regatta this summer and found a boat for them to race. Eager and excited, they observed the interesting Victory 21 design and asked what exactly we were doing, which is when Chris emerged from the belly of the boat and shared that our project list was a bit more than aesthetic like we were planning.

Glassing

Way back when he and his dad first bought the boat to work on together, they did things a bit differently than we would now. For example, to support the underbuilt-and very-soft-foredeck Chris’s dad, Van, fashioned two 2×4’s in a “T” to prop up the underside of the deck where a very young Chris had his first experience with fiberglassing… let’s just say he has come a long way. Our chainplates were also pathetic, the old design consisting of a long piece of angle iron mounted under the port and starboard deck to act as a large backing plate for the three “chainplates” to affix to. Although these simple concepts worked for over 20 years the serious pitfalls of the designs were apparent, especially with the fact that all of the stress and load from the rig went directly into the deck and not the hull, breaking most of the tabbing away from the deck to hull joint over time, decreasing the integrity of the boat altogether.

glassed in knees, thank you Charlie Danu for the foam!

To fix this, Chris decided to copy Avocet’s design and glass in large, overbuilt foam core knees to the hull and deck not strengthening the boat but allowing for a much more robust chainplate to be attached to. After the knees had been glassed in, the attention was turned to the foredeck that, without the 2x4s below bracing the weight, felt much like a trampoline. Chris could have mimicked his father’s 2×4 fix, but instead wanted to strengthen the deck without the need of a brace below. The solution to this was to add beam to beam stringers along the belly of the deck, which would disperse the load of any weight on top. After making a template Chris cut out strips of divinycell and sandwiched layers of 1708 and thickened epoxy until four prominent yet minimal stringers were glassed in. With the structural repairs finished, we could now turn our attention elsewhere. We had only eight days to accomplish our to-do list and there was not one second going to waste!

Day three of Christopher’s Southern California “spa” visit was spent finishing reinforcing the deck and the beginning of the glorious, glorious, sanding that awaited us. Although I work full time five days a week, Chris’s schedule was wide open to tackle the projects alone until I could assist. During my

lunch break, I changed into my boatyard attire (sporting my Neely Boat Works shirt) and got my

hands dirty with sanding the rudder. It was finished in 20 minutes, and I was covered in layers of red, white, and blue dust looking patriotic in the most “boatyard” way. I changed shirts then ran back to work leaving Chris behind to continue the progress. That evening he finished glassing the stringers into place to support the deck, which by morning would be solid. Once showered and free from paint and fiberglass, Chris crawled into bed around 9:00 for a deep night of sleep only to be interrupted by the following daybreak.

Having the fiberglass work complete we shifted our attention the following day to remove what was left of the rub rail. The original screws were mild steel causing them to decay inside the deck to hull joint, very reminiscent of the procedure we performed on Avocet’s deck to hull joint. Having the prior experience came in handy as I stepped in and took over the project, allowing Chris to continue with the dreaded sanding. Armed with our Makita drill I made holes around the sheared-off bolts then pulled out what was left of the metal using pliers, kind of like the classic game “Operation.” It took some time, but with the screws removed, we could fill the holes with epoxy, then sand some more. We routed out the boat’s spider cracks that reached up to her sides like stretch marks, which was appropriate for a vessel this age. Once all voids were traced we faired them using Systems 3, a product we wish we had used above the waterline on Avocet since the consistency was premixed and reliable, not creating pinholes like the US Composites fairing filler/epoxy combo. As the sun began to set, we opened our little cooler and reached for refreshments, Chris accidentally christening the trailer trying to pop a cap off and shattering the beer bottle in his hand. To replace the drink that was accidentally gifted to Poseidon I handed him a Spindrift, our latest libation obsession, and appreciated a good day of work. Our once royal blue boat was now stark white, showing all of her faults, looking naked and vulnerable. Chris wore most of her blue paint on his forearms and around his face where his respirator wouldn’t reach, looking like he got in a fistfight with Papa Smurf. The hard parts were over, it was all rolling and tipping from here.

- what lied beneath the rub rail track

- sanding away

- faired and ready for primer!

- glass repair needed…

Painting the Top Sides

After some much-needed coffee, we started our day around 10:00, feeling the full effects of the prior day’s hard work. Our bodies were sore from standing, but we were incredibly thankful for our new Bosch GET65-5 sander that we wish was in our tool kit when Avocet was on the hard. It is heavier than our Makita orbital, but far more efficient making the physical exhaustion well worth it in the end. The pink patches of fairing compound we spread the evening prior were ready to be sanded along with the epoxied deck to hull joint, giving us a smooth surface for primer. It took two hours but by noon the sanders were retired and the boat was wiped down with an acetone dampened microfiber to remove any leftover debris. Together we mixed and filtered the two-part primer that looked like mud, filling a paint tray and rolling it on in even layers. When 2:00 p.m. rolled around the boat was an awful shade of blush, but all smooth and one color ready to receive her new top paint. The wind picked up and the sun was warm, kissing our exposed skin between the patches of paint and dust that clung to our bodies. We cleaned up our workspace knowing that there was nothing more we could do until the primer dried completely, using it as an excuse to take the mothership sailing with special guests Mama Neely, and our friends Heather and Baron from S/V Remedy.

- Removing the boot stripes

- finishing touches before primer

- blank canvas!

With a renewed sense of motivation and a desire to sail we felt the fire under us grow hotter as the day to paint had finally arrived. We chose to go with Awlgrip paints since we were impressed by the application, result, and durability on Avocet. Considering the Victory is only in the water (usually fresh) a few times a year we decided that this paint would be a good option and started to browse the catalog for her new color scheme, ultimately landing on red inspired by an important tradition which we will touch on later. Dale, the master painter in Ventura Harbor Boatyard and a good friend of ours, pointed us in the direction of which shade of red to use. Chris cracked open the can of paint and got to work rolling and tipping all while our third crew member (the camera) captured a timelapse of the process.

I arrived right when Chris had reached the stern, working around to the starboard side. He rolled the paint with his right hand while holding the painters’ tray in his left, swapping for the paintbrush that he had clenched in his teeth to tip creating a glossy uniform finish. He was a machine working back and forth in swift movements, careful not to miss any spots. Although it was only the first coat we were impressed by the smooth application and the lack of “waves” in the hull that is usually caused by orbitals – the main reason Chris longboard-sanded Avocet for the finished look. Not only were we far more strapped for time with this boat that did not allow longboarding in the timeline, but it was also not really necessary as mentioned prior the boat is only is used a few times a year and is constantly getting beat up by competition (specifically around the marks). Because of this we also decided to roll and tip rather than spray as we did on Avocet.

I arrived right when Chris had reached the stern, working around to the starboard side. He rolled the paint with his right hand while holding the painters’ tray in his left, swapping for the paintbrush that he had clenched in his teeth to tip creating a glossy uniform finish. He was a machine working back and forth in swift movements, careful not to miss any spots. Although it was only the first coat we were impressed by the smooth application and the lack of “waves” in the hull that is usually caused by orbitals – the main reason Chris longboard-sanded Avocet for the finished look. Not only were we far more strapped for time with this boat that did not allow longboarding in the timeline, but it was also not really necessary as mentioned prior the boat is only is used a few times a year and is constantly getting beat up by competition (specifically around the marks). Because of this we also decided to roll and tip rather than spray as we did on Avocet.

“More paint!” Chris said as he continued the red rampage. Still wearing my work clothes (specifically my white T-shirt) I carefully brought him the mixing container filled with the paint he had filtered and let him fill the tray while I stood out of the splash zone. With the camera in my hands, I captured the last bit of white being covered by the rich red, Chris’s reflection bouncing off the hull as he continued to paint vigorously. He dropped his applicators and stood back, flecks of red splattered on his arms and cheeks from working so quickly with the roller, his smile pushing the red specks up like freckles as he admired his work. We both noted a few oddities on the port bow (where he started) but were positive after it was sanded and the second coat was applied that it would not be an issue. I was thrilled to witness this big moment, as we were seeing the light at the end of the tunnel and the start of a new beginning for our little boat. It was a bittersweet process to have sanded away the work Chris and his dad did all those years ago, but I’m sure he would be proud of us and the accomplishments we have made on not only the Victory, but also on Avocet, and in life in general.

- The last photo of Chris and “Christopher”

- seeing RED!

Rigging

The first coat was finished and now all we had to do was wait until tomorrow when we could apply the second. I returned to work while Chris shifted his focus towards rigging. We are fairly certain the rigging on the Victory was original (from the ’60s) and we never gave it much of a second thought until we were racing in the 2019 High Sierra Regatta and our cap shroud chainplate popped out of the deck and our backstay failed causing the mast to bonk me on the head when I was sitting on the foredeck after getting the whisker pole into position. Although we received a “Did Not Finish” for that race, we still placed 6th out of 13 boats which isn’t too bad considering the events that took place. That was the last time we raced the boat and what cemented our desire to kickstart this refit.

In 2020 we were laser-focused on Avocet’s projects in the boatyard, while also battling the various other trials that the infamous year kept stacking up against us. Needless to say, we had no spare time for the Victory and since the regattas were all canceled we decided to push off the refit until 2021, which came a lot faster than we had anticipated leading us to the crunch time of 2 weeks before the race. Better late than never I suppose!

Chris had saved the spare stainless metal we used for our bulwark build and measured the pieces out to be fabricated as brand new chainplates for the Victory which would be fastened to the freshly fiberglassed knees he had created in the hull earlier in the week. This system would allow us to push the boat harder than before since the rig would be so well supported. After some research and conversations with our friend, local rigger Kim Weir and surveyor Ross Hubbard (both proper legends in their respective fields) we decided to swap the wire rigging for Dyneema which would reduce the weight significantly above the waterline. Although familiar with the process and technology it was a new concept for us to be implemented on the boat and we were glad to have experienced friends giving their gracious guidance.

Our friend and dock neighbor Ryan from S/V Appa kindly plasma cut our new stainless chainplates out for us after Chris took the precise measurements. One day later the six pieces were in our possession, perfectly cut and ready to be installed. They looked nothing less than pristine and were quite frankly a bit overbuilt, but far superior to the prior chainplates which were essentially just a through bolt with an eye where the turnbuckles attached. With real chainplates and knees to attach them to we were confident our rig would be sound for years to come.

- Thank you Ryan!!

- Not going anywhere

- we will fix the deck later

Back on the dock Chris laid out the new Dyneema rigging and recruited the help of Mitch to teach him the best way to create the proper splices for the rigging since Mitch and his partner Quincey replaced the wire rigging on their Kelly Peterson 46’ Esprit with synthetic three years back. The sun was hot as the cement docks absorbed the rays, the boys sitting on beach towels and seeking shelter under a light diffuser held by a C-stand… Chris’s camera gear earned a dual-use badge. Together Chris and Mitch spliced all of the rigging in four hours, just in time to catch the sweet afternoon wind in our sails, marking the end of day five.

Bottom Paint

With the chainplates installed and our rigging fitting neatly we returned to painting. Instead of opting for real bottom paint, we decided to use the 2 part epoxy barrier paint, Tuff Stuff, which Chris will sand and burnish later when we have more time. Since the boat lives out of the water 90% of the time the lack of proper bottom paint will be fine, and far better than before where she basically was bare before. Chris was quick to mix and roll the paint onto the freshly sanded bottom, the grey complimenting her glistening red topsides. After a three-hour dry time, we finished off the painting project by getting our hands messy and adding our handprints on the keel, something I wish we had done when Avocet was on the hard. We stood back and smiled, a full transformation squished into a little less than a two-week period. What once was blue is now red, signifying a new chapter for the Victory and her crew, determined to get a W on the water.

I had the honor of pulling the blue tape, which is arguably the most satisfying part of any painting project. The crisp and clean lines between the red and grey were sharp and as straight as an arrow. Chris had struck the waterline the night prior using a laser level, yet again another item we wish we had when in the boatyard with Avocet.

Finishing Touches

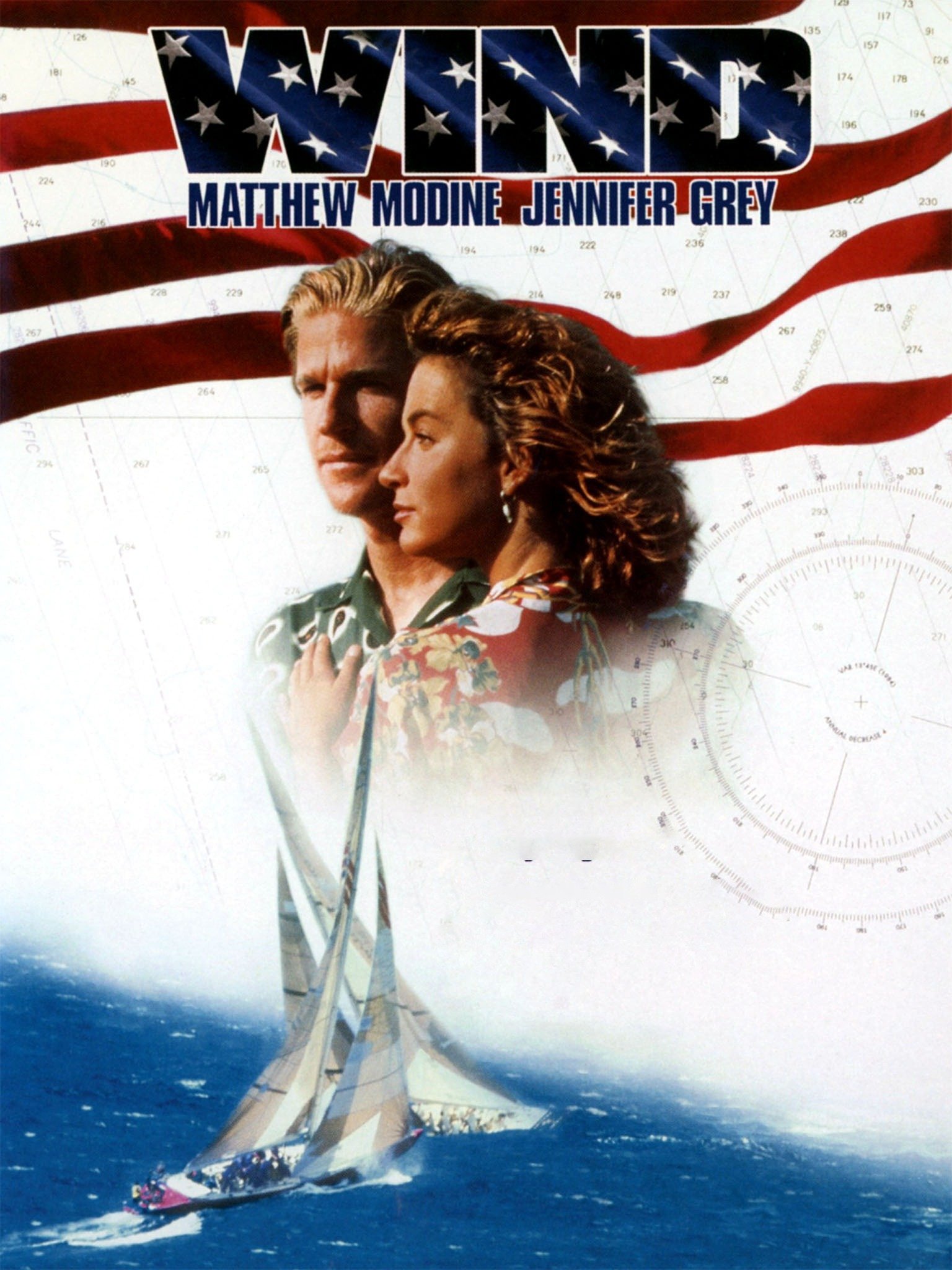

The afternoon sun began to set, stretching shadows across the boatyard. Chris squatted into a warrior-like stance, his shadow following his lead, paying tribute to the 1992 movie Wind, one of our favorite films. It has been a long-standing tradition to watch Wind prior to every regatta, in hopes we can channel Kate Bass and Will Parker to display our best racing on the water. This movie and the events it was based on have influenced our sailing in more ways than one, which is why we are pleased to announce the official name change of our Victory 21 from Christopher to Geronimo to commemorate the film’s 1987 America’s Cup-winning boat.

The afternoon sun began to set, stretching shadows across the boatyard. Chris squatted into a warrior-like stance, his shadow following his lead, paying tribute to the 1992 movie Wind, one of our favorite films. It has been a long-standing tradition to watch Wind prior to every regatta, in hopes we can channel Kate Bass and Will Parker to display our best racing on the water. This movie and the events it was based on have influenced our sailing in more ways than one, which is why we are pleased to announce the official name change of our Victory 21 from Christopher to Geronimo to commemorate the film’s 1987 America’s Cup-winning boat.

Our renaming ceremony was tabled until we reached the lake, where the Victory’s new name would be placed on her transom with vinyl, cut by our friend Keith. As the moments in the yard were fleeting, we finished putting the mast back together after the failing paint had been sanded away, leaving nothing but shining bare aluminum. Together we lifted the mast onto its block for transport then grabbed the drill and impact driver to reinstall the rub rails. Mitch and Quincey stopped by on their jog to take a look at the “final” results, where we handed them an old racecourse to study for the weekend. The following day we would be lake bound, ready for the regatta and putting our hard work to the test.

We arrived in Ventura on July 4th during the wee hours of the morning with a blue boat and a plan. Eight days later on July 15th we were leaving Ventura with a red boat in tow, after days of hard work and pouring love into this floating time capsule of memories. The crimson red paint reflected off her hull as we drove through the various landscapes on our five-hour drive. Chris’s gaze kept shifting from the road ahead to his rearview mirrors, undoubtedly impressed with his work and admiring the little boat’s newly instated beauty.

It was 7:00 pm when we arrived at Huntington Lake, parking the truck and trailer outside the cabin we were staying at. Exhausted from the long week of work and drive combined, we put the new vinyl name on the transom with the help of Chris’s sister (who is a talented artist with an eye for perfection), then went to bed doing our best to sleep with the anxious excitement that settled in our stomachs. Quincey and Mitch set up their tent outside, embracing the great outdoors and undoubtedly also squeezing as many “Z’s” as possible in preparation for the days to follow.

The next morning greeted us with the smell of coffee and pine trees wafting through the lakeside cabin. We woke up early, meeting our two young nephews downstairs and putting them to work. Truman, who is 7, carefully assisted Chris in guiding the bumper material into the track we had installed back in Ventura. With the rub rail finished we trucked the boat down to the launch ramp where we pulled up alongside fellow Victory sailors Don, Wendy, Matt, and Laura to rig our boat beside them. They didn’t recognize us at first, our once blue boat now cherry red, and were quick to inspect our handy work.

Eight days of hard work resulted in a beautiful transformation. It was emotional and fulfilling to sail on our home lake after a Covid-induced hiatus, with a boat that laid the foundation of not only our relationship but also our sailing adventures. Joined by the fellow Victory fleet we completed our official renaming ceremony, dedicating the vessel to Zephyrus, Poseidon, and most important of all Chris’s father, Van, who had sparked this crazy sailing endeavor of ours and is undoubtedly present every time the wind fills our sails (or when a minor project occurs). As we crossed the finish line marking the end of our ninth regatta together we are extremely thankful for those who have inspired us to persevere. Chris and I would like to formally dedicate Geronimo’s transformation to the Fresno Yacht Club Victory 21 fleet, for supporting us on and off the water since the beginning- we hope that we will continue to make you proud.

Cheers to the 68th annual High Sierra Regatta!

Fai Winds from the crew of Geronimo,

Marissa & Chris

0 Comments